Welcome to our Encon Solutions!

Why Condensate Recovery?

Every 6 Deg rise in feed Water Temperature gives 1% fuel savings

Reduces the fuel cost

Recover pure form of water

Minimises the need for makeup water and associated costs

Reduces the disolved oxygen

No electricity required

Reduces the need for boiler blowdown

Reduces the TDS in the boiler feed water

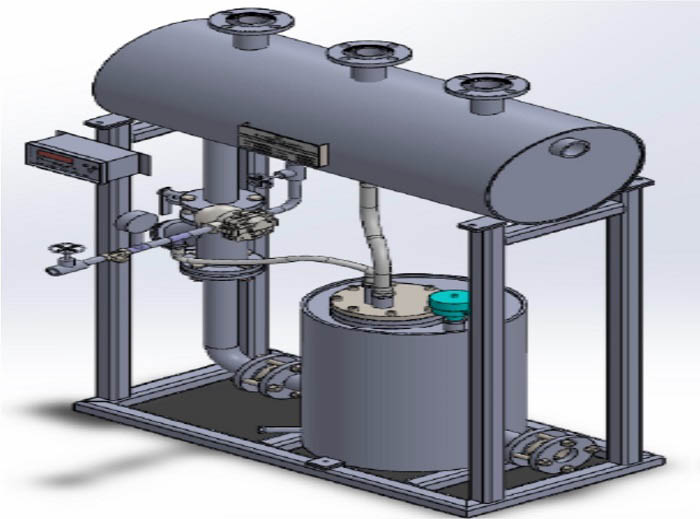

Principle of Operation

Rice mills often face issues such as:

Pressure Powered pump operated on positive displacement principle. By gravity the condensate in the pump body through the inlet DCV causing the float to rise. The steam above the condensate escapes through exhaust valve which Is open at this position. As the chamber fills the float rises.

At a certain position the valve linkage changeover is Engaged with snap action opening the inlet valve and closing the exhaust valve. This snap action linkage ensures a rapid change from filling to pumping stroke. As pressure inside the pump exceeds the total back pressure, condensate forced through the outlet DCV to the return condensate line.

As the liquid level falls within the pump body the float re-engages the valve change over linkage by snap action, causing inlet valve to close and the exhaust valve to open. The steam escapes through the exhaust valve and the cycle repeats. Thus the function of the pump depends upon mainly filling head and motive steam pressure.

The flash steam should be connected to the low pressure process up to a pressure of 1.5 bar (g). The safety valve fitted on the Flash Vessel ensures that the flash steam pressure does not exceed 2 bar (g). Further, as an additional safety feature, a float trap is provided to drain condensate in case of flooding, thereby ensuring, desired flash steam dryness fraction and optimum performance.

Commonly Asked Questions FAQ

Regarding Rice Mills

Why is steam efficiency critical in rice milling?

In rice mills, steam is necessary for operations including drying, steaming, and parboiling.

Effective steam management guarantees:

Consistent quality of the final output.

A decrease in energy usage.

Reduced expenses for operations.

Improved sustainability through reduced water and fuel waste.

How do rice mills profit from a condensate recovery system?

Hot condensate, or water made from steam, is collected and recycled back into the boiler using a condensate recovery system. Benefits include: • Lower fuel expenses due to boiler feedwater being preheated using recovered heat.

Less waste, lower expenses, and less water use.

Extended equipment life due to increased boiler efficiency.

Improved sustainability of the environment through emission reduction.

What role do steam traps play in rice mills?

Steam traps remove condensate from steam systems while preventing steam loss. Properly functioning steam traps:

Ensure consistent steam pressure and temperature.

Enhance process efficiency and product quality.

Prevent energy loss, reducing fuel costs.

Minimize downtime caused by system inefficiencies or failures.

How often should steam traps be inspected in rice mills?

Steam traps should be inspected at least once or twice a year to ensure they are functioning correctly. Regular audits can identify faulty traps, helping to maintain efficiency and avoid unnecessary energy losses.

What kind of savings can be achieved with condensate recovery in rice mills?

Recovering and reusing condensate can lead to significant energy savings. For example:

Every 6°C increase in feedwater temperature can save approximately 1% in fuel costs.

Reduced water and fuel consumption result in lower operational expenses over time.

Are Encon Solution’s systems compatible with existing rice mill infrastructure?

Indeed, our steam traps and condensate recovery systems are made to work in unison with your existing steam configuration. In order to minimize installation disturbance, we tailor our solutions to your rice mill's particular requirements.

How do Encon Solution’s products support sustainability in rice mills?

Our solutions help rice mills reduce their environmental footprint by:

Conserving energy through heat recovery.

Reducing fuel consumption and emissions.

Minimizing water usage and wastage.

What challenges in rice milling can Encon Solution address?

We address common challenges, including:

High energy costs due to steam wastage.

Inconsistent steam pressure affecting process quality.

Inefficient steam systems leading to increased fuel and water use.

Equipment inefficiencies causing downtime.

Do you provide support after system installation?

Yes, Encon Solution offers comprehensive support, including:

Installation assistance.

Regular maintenance and troubleshooting.

Steam trap audits and replacement services.

Ongoing technical support to ensure optimal performance.

How do I get started with Encon Solution for my rice mill?

Indeed, our steam traps and condensate recovery systems are made to work in unison with your existing steam configuration. In order to minimize installation disturbance, we tailor our solutions to your rice mill's particular requirements.

Request a Quote

Fill all information details to consult with us to get sevices from us

Get in touch

For more questions or detailed assistance, feel free to reach out to us at Contact Us. We're here to help your rice mill operate more efficiently and sustainably!

Call us on

+91 8818046000